RGB-IR cameras: How do they work and what are their main components?

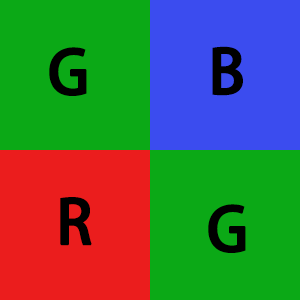

Conventional color camera modules are equipped with color filter arrays (CFAs) with BGGR modes that are sensitive to visible and infrared (IR) light wavelengths. This leads to color distortion and inaccurate IR light measurements, degrading the quality of the final RGB image. This makes it difficult to measure the intensity of IR light in the captured image.

To solve this problem, cameras typically use an IR cutoff filter during the day to prevent IR light from falling on the sensor. At night, they are mechanically removed to allow IR light to enhance low-light imaging. However, this mechanical solution is prone to wear and tear, shortening the life of the camera module.

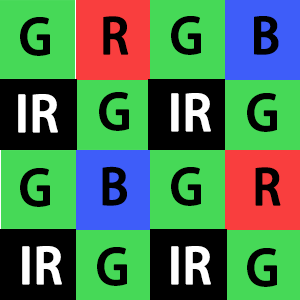

RGB-IR cameras bypass these limitations by using a color filter array (CFA) that contains dedicated pixels for both visible and infrared light. High-quality images can be captured in both the visible and infrared spectral ranges without mechanical intervention, thus preventing color damage. Dedicated pixels can also also facilitate multi-band imaging.

In this article, we will describe how RGB-IR camera modules work and their main components, as well as some key embedded vision applications where RGB-IR cameras are recommended over regular cameras.

How do RGB-IR cameras work?

A standard Bayer CFA format pixel with BGGR mode is shown below.

The specialized pixels of an RGB-IR camera allow infrared light to pass through them. And these pixels help in multi-band imaging. This new CFA with R, G, B and IR pixels is shown below:

Here are some of the advantage of using RGB-IR camera:

- It can be easily adapted to the constantly changing conditions of day and night. This is useful for all-weather imaging.

- Avoiding the use of mechanical filters to switch between visible and infrared light increases the life and stability of the equipment.

- Provides a dedicated infrared channel that clearly separates visible and infrared image data. Helps to accurately measure the amount of infrared light in image RGB and perform color correction to improve the quality of RGB output

How to utilize visible and infrared imaging CFA

Simply using RGB-IR filters is not enough for effective imaging. It is also necessary to select the right components that support RGB-IR imaging.

Sensor: Choose a sensor with IR-sensitive pixels on the CFA. manufacturers such as onsemi and OmniVision offer RGB-IR capable sensors.

Optics: Typically, color camera lenses are equipped with IR cutoff filters to block wavelengths above 650nm. To facilitate RGB-IR imaging, dual bandpass filters, which allow for both visible (400-650nm) and infrared (800-950nm) wavelengths, are chosen in place of traditional IR cutoff filters.

Image Signal Processor (ISP): The ISP algorithmically separates RGB and IR data into separate frames, inserts the processed RGB output, and subtracts IR contamination to ensure accurate color output. In addition, the ISP should be able to output only processed RGB or IR frames as required by the host system.

Common Embedded Vision Applications for RGB-IR Cameras

Automatic Number Plate Recognition (ANPR)

For ANPR, which requires the detection of license plate letters, symbols, and colors under varying lighting conditions, use RGB-IR cameras that reliably capture both visible and infrared images for longer life and improved accuracy.

Advanced Weatherproof Security

With RGB-IR cameras, security applications can overcome the problem of color inaccuracies that hinder object detection. Day or night, these cameras use RGB-IR sensors and dual bandpass filters to capture high-quality images that help extract accurate information for analysis.

Sinoseen is committed to solving problems for our customers, so feel free to contact us if you need a solution to a problem encountered in visible and infrared (IR) imaging.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD