Embedded vision and Machine Vision: Things You need to Know

How do machines “see”? I believe we have all thought about this question. In fact, this mainly depends on embedded vision and machine vision technology. These two concepts are only a hair's breadth apart, and many people often confuse the two.

Both machine vision and embedded vision play an important role in industry, especially in the field of control and automation. Embedded vision systems offer compact efficiency, while traditional machine vision systems offer high performance and versatility. With advances in camera and processing technology, embedded vision has become almost as powerful as machine vision systems. Embedded vision systems integrate the hardware and software components needed for machine vision (image acquisition, processing, and interpretation). Because no external connections are required, embedded vision systems can be used in industries and markets where traditional machine vision systems cannot be applied.

What is machine vision?

Machine vision allows a machine or computer to see and interpret visual information. It does not refer to any one specific technology, but to all systems that can interpret visual information through machines. It is capable of automatically capturing, processing and interpreting visual information around it as a means of making decisions for a variety of industries, such as medical imaging, shop floor assembly, and object recognition.In the previous article we had an understanding of the types of machine vision.

Machine vision systems typically use industrial PCs to handle tasks related to image data. Specialized hardware and software allow for hilarious image analysis and provide the necessary computing power for complex machine vision tasks. Machine vision systems generally include the following components:

- Camera: mostly special cameras customized for industry. Used to capture images or video clips for processing by the main system.

- mage processing software: Not all machine vision cameras are plug-and-play, so specialized software for image analysis and processing is required.

- Lighting: Proper lighting ensures that high quality images are captured. Use lighting techniques such as LED or infrared lighting to optimize image visibility.

- Hardware: Machine vision systems can facilitate data transfer and speed up image processing tasks through the use of frame grabbers or specialized processors.

What is Embedded Vision?

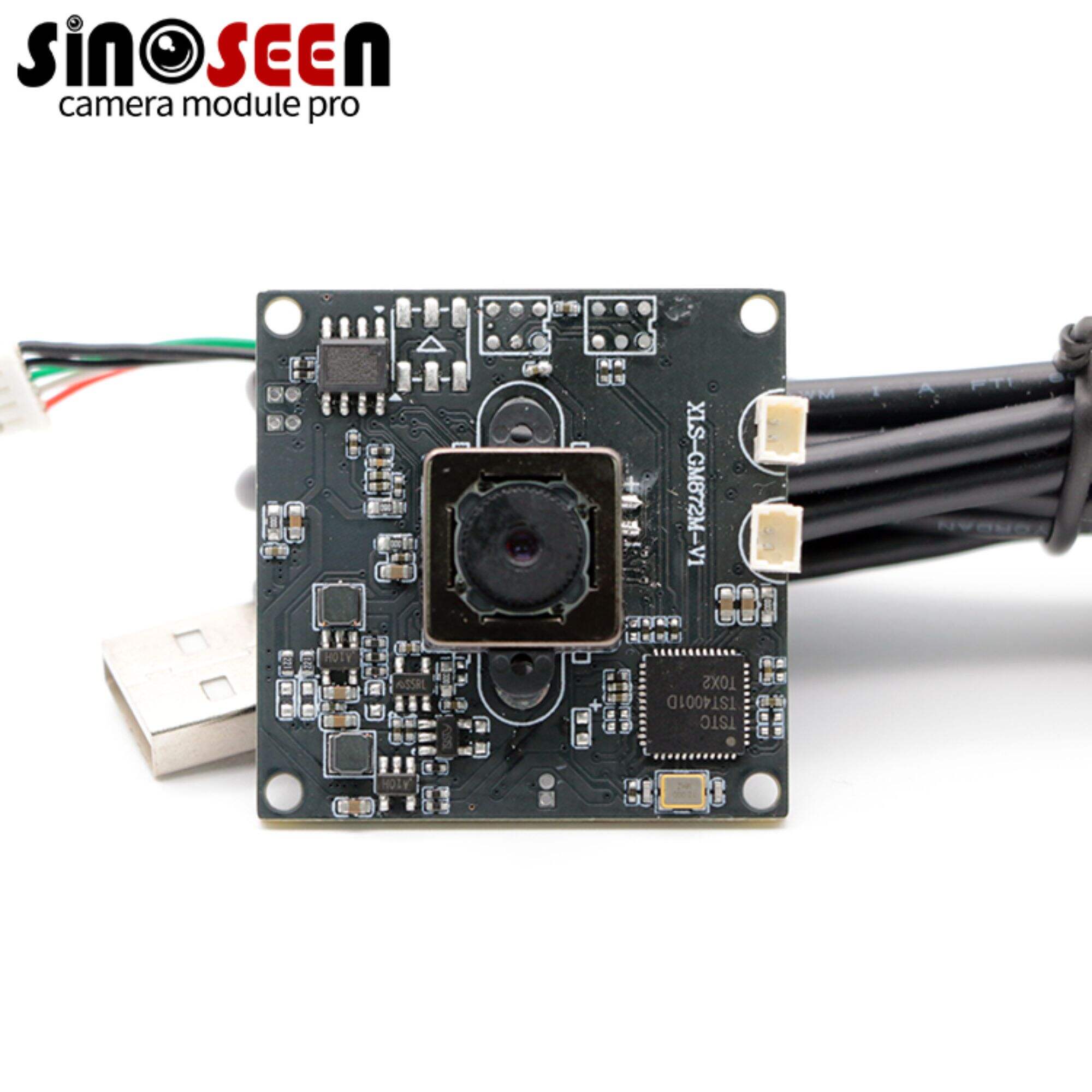

Embedded vision systems differ from traditional machine vision systems in how and where images are processed. Embedded vision systems are all-in-one devices, typically consisting of a camera mounted on an image processor. Since all the equipment is integrated on the board, image capture and processing can be performed within a single device.

Embedded vision systems are characterized by compactness, lower cost and real-time response. Often used in applications where space is at a premium, such as autonomous driving and object recognition functions in drones, embedded vision retains efficient decision-making capabilities while eliminating the bulkiness of machine vision.

Embedded vision systems are undoubtedly easier to use and integrate than traditional machine vision systems, but can be more expensive to install than machine vision due to their customization properties. However, their compactness and the low power consumption required make them relatively cheaper to operate.

On the other hand, embedded vision is actually a part of machine vision, but there are slight differences due to different functions and applications. In terms of current technology, the performance of embedded vision systems is still inferior to that of PC-based systems.

Differences between embedded vision and machine vision

Although both embedded vision and machine vision can help machines see things, there are some differences.

|

Parameters |

Machine vision |

Embedded vision |

|

Image processing |

This is done using a separate PC connected to the machine vision camera |

Use dedicated processors (e.g. NVIDIA Jetson, TI Jacinto, NXP, etc.) |

|

Image analysis |

PC based image analysis |

It mainly uses edge computing and AI/ML/ computer vision algorithms to analyze the device itself. |

|

dimension |

It is large, consisting of a camera system and a separate PC, usually on an industrial or commercial scale |

It's compact. Size is constantly decreasing, although AI performance may be limited in some compact processor families, such as NXP i.MX |

|

cost |

Costs can be high and involve multiple components, such as cameras, PCS, and software that may require a subscription to cloud-based analytics |

They are often more cost effective as they reduce ongoing operating costs. However, depending on the type of camera and processor used, the initial capital expenditure may be higher |

|

Easy to integrate |

Easier to integrate, with a standard interface that connects directly to a PC for immediate operation |

Some engineering expertise is required to integrate, which varies depending on the application and the complexity of the components used. Camera integration may require the assistance of camera experts such as TechNexion |

|

Decision speed |

Fast hardware and software are needed for efficient data transfer and analysis. |

It excels in real-time decision making, as processing takes place on the device and data is quickly transferred to the cloud for analysis without the need for specialized Settings |

|

flexibility |

Universal, through configuration and software, machine vision systems can be used for different tasks |

Designed for specific tasks. Optical components, sensors, processors, and software analytics are selected, tuned, and cost optimized for specific use cases |

Conclusion

Over the years as the amount of computing power that can fit in a compact space has increased, machine learning systems have used smaller and smaller PCs, while the on-board processors in embedded vision devices have become more and more powerful. As a result, the differences between traditional machine vision and embedded vision have become less and less pronounced. In fact, the processing power of the processors in today's embedded vision systems is comparable to the machine learning systems of a few years ago.

Sinoseen has more than 14 years of embedded vision experience, with a professional team, if you want to customize professional camera module equipment for your embedded vision applications, please feel free to contact us.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD