Understanding the Four Basic Types of Machine Vision Systems

Machine vision systems have weaved their way into a number of activities in the industry which include quality enhancements, increased automation and data capture. At Sinoseen, we appreciate that it is imperative to seek for the different types of machine vision systems offered in the market. This article examines the elementary types of machine vision systems and their features in detail.

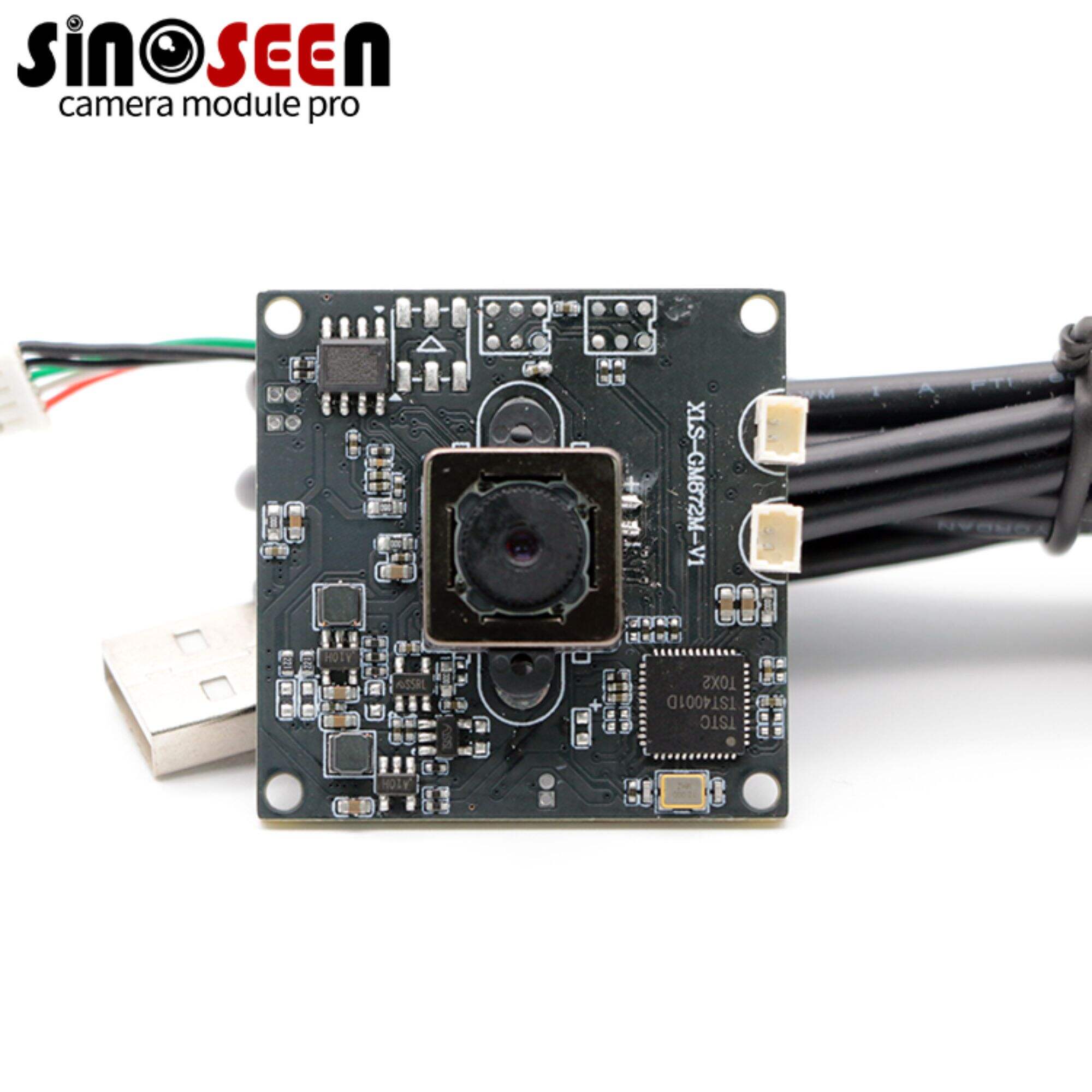

2D vision systems

2D vision systems are one of the most basic and well known types of machine vision systems here they use one camera to capture only 2 dimensional images which are height and width. Due to their power simplicity these systems are most preferred for a number of routine inspection procedures.

Key features

Single camera setup: Only one camera is used in this case which captures two dimensional pictures.

Image processing: Compare to 2-D image processing systems, 2-D image recognition systems work with features instead of images, e.g. extract and analyze edges, contours, and patterns.

Applications: This system is used mainly in surface checking processes, reading of bar codes and basic alignment checking.

3D vision systems

A 3D vision systems help to complete the height and width with depth statistics. These systems can produce three-dimensional presentations of objects’ shape, using specific sensors or algorithms or several cameras.

Key features

Depth perception: Processes and records depth information. This helps to deal with a three dimensional problem more thoroughly.

Advanced sensors: Classification can be achieved by measuring distance through different techniques e.g. laser triangulation and stereo vision.

Uses: Best suited in terms of proper measurement and inspection when it comes to complex geometry.

Color Vision systems

This system acts to extract color information from the image. While monochrome systems operate without bothering about colors, these systems are able to implement color, which is important in many tasks.

Key features

Being color capable: Has cameras that analyzes and captures color images.

Decision making: This feature where color images are analyzed for making categorization.

Applications: Good for color based sorting of products, identification of flaws based on colors, and color dependent quality assessments.

Multispectral and hyperspectral vision systems

These systems utilize a wide variety of the electromagnetic spectrum and take pictures in ranges other than visible light. This means a more detailed investigation of the material characteristics and conditions can be undertaken.

Key features

Variety of wavelengths: Achieves many characterizations of materials by obtaining data in several wavelengths.

Data retrieval: These advanced phenomenoms employ computer program to process the spectral data.

Applications: Good for the material characterization purposes which cut across fields such as agricultural plants and health monitoring and environmental monitoring.

Every machine vision system you choose has its own advantages and is more or less suitable for specific application. Therefore, 2D systems are preferred for their simplicity, 3D systems for their depth perception, color vision systems for their capability da save image in color, while multispectral and hyperspectral systems for super detailed analysis.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD