How to Selecting M12(S-Mount) Lens?The ultimate step-by-step guide

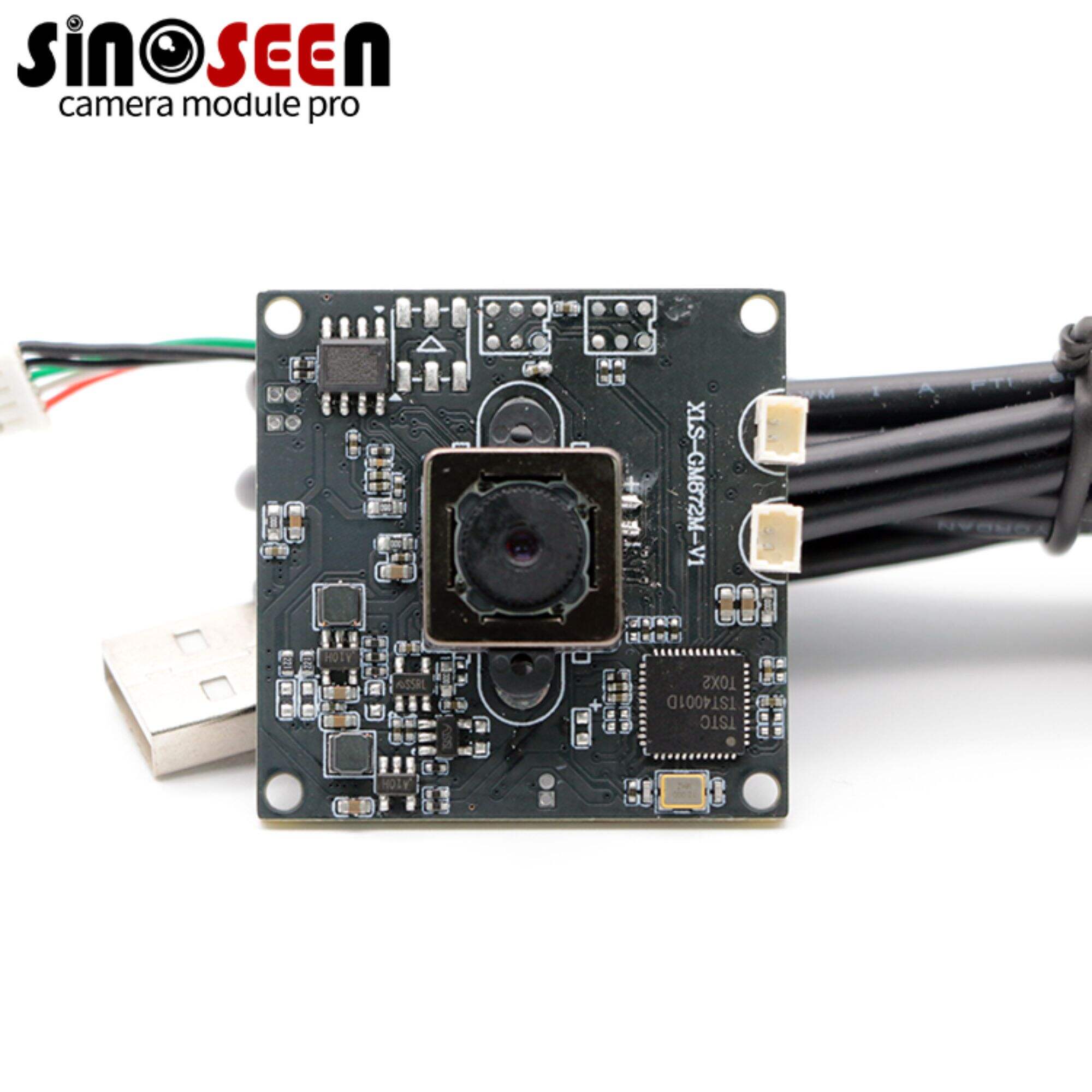

The M12 lens (also known as S-Mount lens) is an essential component in various high-end vision systems. With its compact size and light weight, it is widely used in cutting-edge fields such as machine vision, medical equipment, and robotic automation. Understanding how to choose to pick the right M12 lens is beneficial to improving the quality of images and the accuracy of your system.

What is an M12 lens?

M12 lenses (also known as S-Mount lenses) are standard compact lenses with a 12mm lens thread diameter. as a representative of S-Mount lenses, they meet the needs of high-end imaging in machine vision, medical equipment, industrial inspection and other areas with their compact size and flexible focus adjustment capabilities. m12 lens are usually connected to the camera using interfaces such as M12 Mount, CS-Mount, or C Mount, CS-Mount, or C-Mount to ensure compatibility.We have looked at the types of lenses earlier.

What should I consider when choosing an M12 lens?

As the use of M12 lenses gradually becomes more common, choosing the right lens is especially important. The right M12 lens will allow the equipment to achieve optimal performance and reflect better image quality. Here are some factors to consider when choosing an M12 lens:

Compatibility with equipment: It is important to ensure that the selected m12 lens is compatible with your equipment. This includes checking the m12 lens mount interface, resolution, sensor size, and so on. Make sure that the lens is perfectly matched with your equipment in order to avoid any problems with the image quality.

Field of View: The FOV determines the extent of the scene that the lens is able to capture. The wider the field of view, the greater the coverage, while the narrower the field of view, the greater the magnification.

Focal Length: The focal length is a key parameter that affects image magnification and field of view. A longer focal length provides greater magnification and a shorter focal length provides a wider field of view.

Aperture: The size of the aperture determines how much light can pass through the lens to reach the sensor. The larger the aperture, the more light can be captured in low-light conditions. However, it may also result in a shallower depth of field.

NIR Sensitivity: NIR refers to the region of the electromagnetic spectrum near the visible band (750 - 2500 nm). For equipment that needs to work within the NIR spectrum, choosing the right m12 lens can improve performance in low light.

Image Quality: Image quality includes, but is not limited to, sharpness, contrast, and chromatic aberration. Ensuring that the correct M12 lens is selected ensures that it will provide clear vision in all conditions.

Distortion: Distortion is a deviation between the image and the original image. It is usually caused by the curvature of the lens elements. Choosing a lens with low distortion ensures a high degree of image accuracy.

Cost: Although c/cs interface lenses offer better quality, m12 lenses are preferred. Its a low-cost compact alternative to standard size lenses for a variety of applications.

In conclusion, for choosing the right M12 lens, we need to strike a balance between size and performance. The smaller the lens base, the more confined the construction and also the poorer the performance. However, compared to other lenses, the M12 lens is easier to customize because of its simple design.

Popular Applications of M12 Lens (S-Count Lens)

M12] lenses play a vital role in several fields due to their excellent performance.

Machine vision: The M12 lens is used in automated production lines to capture images of objects and analyze them with processing software to improve productivity and accuracy.

Industrial Inspection: In industrial inspection, M12 is used to inspect machinery and other equipment, and is used to detect phenomena such as wear and tear and damage to the equipment, so that it can be replaced and maintained in a timely manner to ensure industrial safety.

Medical equipment: M12 lenses are often used in medical treatment for endoscopes and surgical m12 camera. Through its small size, it can discover the internal conditions of the human body and help medical personnel make the right decisions. It is an excellent choice for high-precision medical imaging.

Robotics and Automation: M12 lenses are used in robotics and automation to provide visual data to robots to help or guide them in performing tasks.

M12 lens types and their associated features

how to choose a lens for a camera?The versatility of M12 lenses is key to their ability to be used in a wide range of applications. Understanding the different types of m12 lenses and their characteristics can help us choose the most appropriate lens for a particular application. Below are a few common types of M12 lenses and their key features:

Fixed Focal Length Lenses: These lenses have a fixed focal length and provide stable image magnification. They are suitable for applications that require a consistent field of view and precise imaging, such as industrial surveying and fixed-position surveillance systems.

Wide Angle Lenses: Wide angle M12 lenses offer a wider Field of View (FoV) than standard lenses and are suitable for applications that require coverage of a larger area, such as indoor surveillance or panoramic cameras.

Manual Focus Lenses: Manual focus lenses allow the user to adjust the focal length as needed for a sharp image. They are suitable for applications where the scene is relatively static or where there is a specific need for quick adjustments.

Autofocus Lenses: Autofocus lenses adjust focus automatically with a built-in motor and are suitable for dynamic scenes or tracking of moving targets, such as mobile surveillance or robotic vision.

Plastic Lenses: Plastic M12 lenses are favored for their light weight and cost effectiveness. While perhaps slightly inferior to glass lenses in terms of optical performance, they are a good choice in cost-sensitive applications.

Glass Lenses: Glass M12 lenses offer greater optical clarity and temperature resistance for applications where image quality is critical, such as high-end medical imaging or precision industrial inspection.

Special Feature Lenses: Some M12 lenses may feature special optical coatings or designs, such as anti-reflective coatings, IR cut-off filters, or low-dispersion glass, to meet specific visual needs.

Each M12 lens type has unique advantages and limitations, and selection requires consideration of the specific needs of the application. Examples include the consistency and reliability of fixed focal length lenses, the wide field of view of wide-angle lenses, the flexibility of manual and autofocus lenses, and the trade-offs in cost and performance between plastic and glass lenses.

Choice of Lens Material

Choosing the right lens selection material is one of the key factors in ensuring that m12 lenses perform to the needs of a particular application. There are two main lens materials on the market: plastic (Plastic) and glass (Glass), each of which has unique advantages and limitations. Plastic lenses are favored in certain applications for their cost-effectiveness and lightweight advantages, while glass lenses are more desirable in high-end applications for their superior optical performance and durability. When selecting an M12 lens, users need to consider factors such as optical performance, durability, weight, size, cost, and the need for special coatings to ensure that the selected lens will meet the performance requirements and budgetary constraints of their particular application.

Conclusion

In conclusion, choosing the right M12 lens is all about the performance and functionality of your equipment. When choosing an M12 lens, focus on its compatibility with your equipment, field of view, focal length, distortion, image quality, NIR sensitivity, cost, and other factors. Of course, the material of the lens is also one of the influencing factors. At the same time, M12 lenses require different conditions in different application environments (machine vision, medical equipment, etc.), and we need to consider these factors comprehensively to choose the lens that best meets our needs.

With nearly sixteen years of experience in embedded vision, Sinoseen can help you select the right lens to meet your unique application requirements. At the same time, we can help you eliminate issues such as lens vignetting and color distortion.

So if you're looking for help in choosing the right lens or integrating the camera into your embedded vision product, please contact us.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD