The Role of DVP Camera Modules in High-Speed Imaging Applications

Understanding DVP Camera Modules in High-Speed Imaging

Core Components Enabling High-Speed Performance

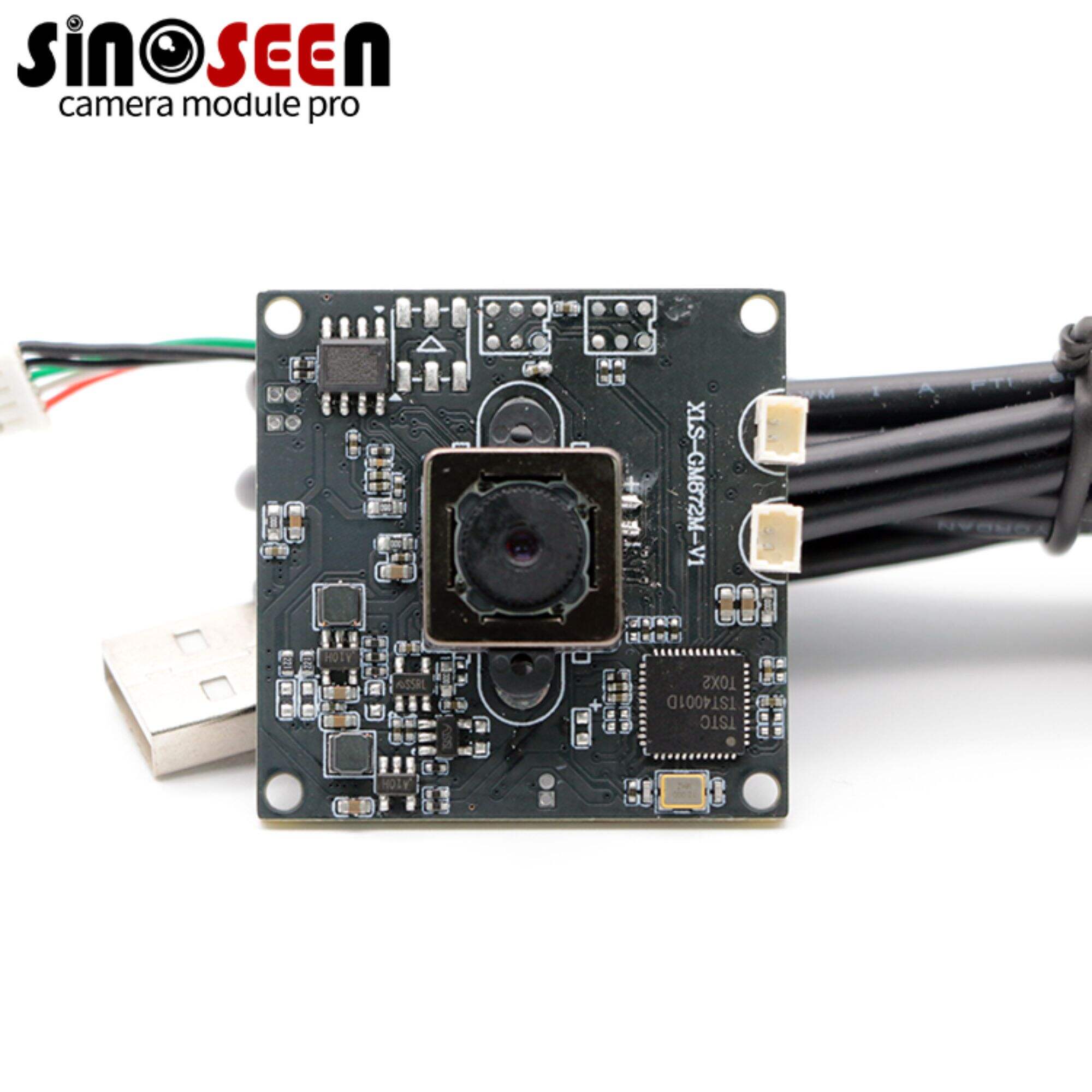

DVP camera modules boast key components that enable high-speed performance, making them ideal for dynamic imaging environments. The image sensors, particularly CMOS sensors, are integral in capturing fast-moving objects with minimal motion blur through features like rolling and global shutter mechanisms. These sensors convert light into electronic signals efficiently, allowing detailed capture of rapid movements. Processing units in these modules handle rapid image processing to quickly adjust exposure and frame rate settings, essential for high-speed captures. Data interface structures, such as parallel data paths, enhance the speed of data transmission, providing real-time processing and instant feedback crucial for applications demanding quick responsiveness.

DVP Interface Advantages for Rapid Data Transmission

The DVP interface greatly enhances the rapid transmission of image data between the camera module and processing units, ensuring minimal latency for real-time performance. By utilizing a parallel data interface, DVP modules can transfer multiple data bits simultaneously, significantly increasing throughput compared to serial interfaces. This facilitates higher frames per second (FPS), crucial in applications like industrial automation where speed correlates with efficiency. Moreover, the cost-effectiveness of DVP technology in mass production offers a valuable investment for businesses seeking high-speed imaging solutions without incurring steep expenses. Considered a robust choice for applications such as face recognition camera systems, DVP interfaces ensure seamless operation in environments demanding quick and accurate image analysis.

Key Applications of DVP Modules in High-Speed Contexts

Industrial Automation and Quality Control

In industrial automation, where precision and speed are crucial, DVP camera modules are extensively utilized to ensure the accuracy of quality control processes. These modules verify product quality directly on production lines, offering real-time insights that enhance operational efficiency. By leveraging their high-resolution imaging and rapid frame capture capabilities, they detect defects instantaneously, minimizing wastage and rework. Furthermore, machine vision applications use DVP technology to analyze production metrics, optimizing operations through immediate feedback loops based on visual data. This integration not only boosts production quality but also significantly increases throughput, highlighting the indispensable role of DVP technologies in modern manufacturing systems.

Face Recognition Systems for Real-Time Security

For security applications, DVP camera modules are pivotal in the development of face recognition systems, which demand rapid image capture and processing for robust safety measures. These systems rely on sophisticated algorithms that require precise image data to deliver accurate and immediate identification and verification of individuals. Incorporating DVP modules ensures that the system minimizes lag, which is essential in high-stakes environments like airports and public events. Real-world implementations have shown that DVP-equipped face recognition systems markedly improve accuracy, thus contributing to enhanced security and safer public spaces.

High-Speed Medical Imaging Diagnostics

In the medical field, DVP camera modules are game-changers for high-speed imaging diagnostics, enhancing patient care by providing real-time insights during procedures. This is particularly important in operations such as endoscopy or vascular surgeries, where high-speed imaging can offer superior visualization, enabling quicker decision-making by medical professionals. DVP technology amplifies the resolution and speed of medical imaging equipment, allowing detailed capture of moving organs without distortion. Consequently, studies indicate that hospitals using DVP-embedded imaging systems benefit from faster diagnostic turnarounds, ensuring patients receive timely and effective treatments.

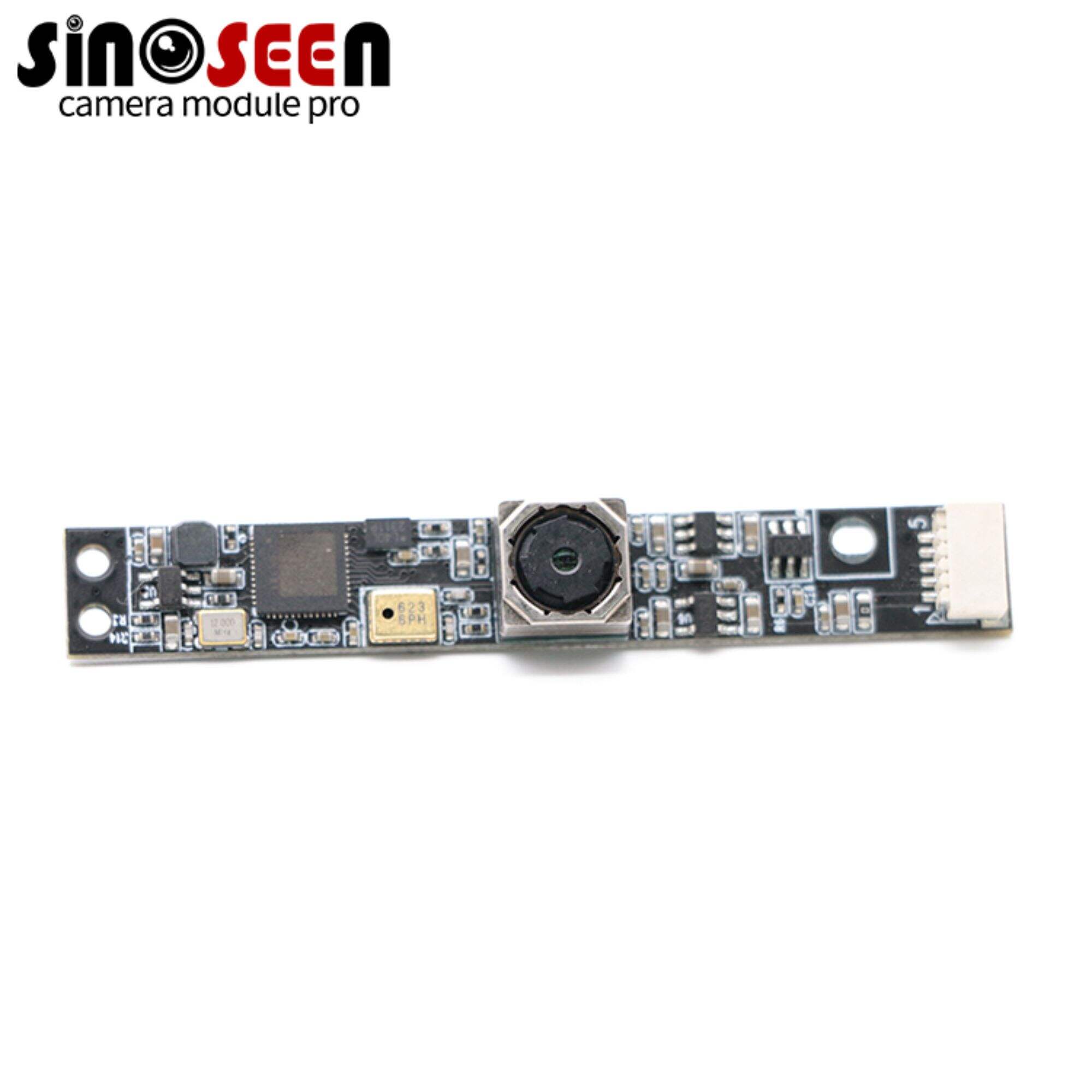

Product Spotlight: Strip Shape 8MP Raspberry Pi Camera Module

IMX179 Sensor: Delivering 8MP Clarity in Compact Designs

The IMX179 sensor in the Strip Shape 8MP Raspberry Pi Camera Module is renowned for high-resolution imagery in a compact design, ideal for space-constrained applications. Its advanced technology enhances light sensitivity and minimizes noise, improving image quality even in varied lighting conditions. Capturing images at 8 megapixels, the IMX179 facilitates detailed analysis, crucial for personal projects and commercial applications. Empirical studies highlight the sensor's effectiveness in delivering clear and vibrant images, reinforcing its reputation in the digital imaging sector.

USB2.0 Integration for Seamless High-Speed Data Transfer

Integrating USB2.0 technology in the Raspberry Pi Camera Module facilitates seamless high-speed data transfers, essential for real-time applications requiring rapid data processing. This integration ensures consistent performance with minimal latency, a critical aspect for live streaming or instant video processing uses. The USB2.0 connection broadens the camera’s applicability across different devices, enhancing its utility in both professional and recreational settings. Reports on USB2.0 speeds validate a noticeable improvement in data handling efficiency, underlying its importance in modern camera technologies.

Applications: From Smart Devices to Industrial Monitoring

The versatility of the Strip Shape 8MP Raspberry Pi Camera Module allows its application across a range of domains, from smart devices to industrial monitoring systems. Its compact form factor is particularly advantageous in smart devices, promoting innovative solutions in IoT and smart home setups. For industrial purposes, it offers enhanced monitoring capabilities, aiding in anomaly detection and operational efficiency. Industry surveys indicate a rising trend in adopting Raspberry Pi cameras across various sectors, driven by their affordability and flexibility.

Choosing the Right DVP Module for High-Speed Needs

Balancing Resolution and Frame Rate Requirements

Choosing the right DVP (Digital Video Port) module requires a careful balance between resolution and frame rate to meet specific application needs efficiently. Higher resolution provides greater image detail but often demands more processing power and storage capacity, which can lead to lower frame rates. Conversely, prioritizing frame rate enhances the ability to capture fast-moving objects but might compromise the clarity of individual frames. In sectors like industrial automation, careful balancing of these factors is crucial for optimizing performance without sacrificing quality. This approach not only ensures that devices perform efficiently but also maximizes their utility in various high-speed scenarios.

Power Efficiency in Demanding Imaging Scenarios

Power efficiency is a critical consideration when selecting a DVP module, especially in scenarios where imaging technology is heavily deployed, such as in remote or mobile applications. Modules designed with low power consumption extend operational life and reduce heat generation, which is vital for long-term deployments. Recent innovations in power management technologies have enabled DVP camera modules to perform effectively without draining resources, making them ideal for battery-powered or energy-sensitive environments. For example, data from recent benchmarks indicates a 30% decrease in power usage with advanced DVP modules compared to older technologies, highlighting the significance of efficiency in maintaining performance over extended periods.

FAQ

What is the primary use of DVP camera modules in industrial automation?

DVP camera modules are primarily used in industrial automation for precision and speed, ensuring accurate quality control processes and real-time insights on production lines.

How does the DVP interface enhance the functionality of face recognition systems?

The DVP interface enhances the functionality of face recognition systems by providing rapid image capture and processing, minimizing lag and ensuring accurate identification and verification.

Why is USB2.0 integration important for Raspberry Pi Camera Modules?

USB2.0 integration is crucial for Raspberry Pi Camera Modules because it facilitates seamless high-speed data transfers, minimizing latency and supporting real-time applications requiring rapid data processing.

How do DVP modules contribute to power efficiency in imaging applications?

DVP modules contribute to power efficiency through advanced power management technologies, supporting long-term deployments by reducing power consumption and heat generation.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD