Applications and Innovations of Camera Modules in Industrial Automation

Camera modules play a crucial role in industrial automation, revolutionizing various processes and applications. With advancements in technology, camera modules have become more compact, affordable, and capable of capturing high-quality images. In this article, we will explore the applications and innovations of camera modules in industrial automation, highlighting their benefits and impact on efficiency and productivity.

Quality Control and Inspection

Automation systems in the industry with camera module are for quality control and inspection. The image processing modules make it possible to achieve really high-resolution image shooting. Such images can be very detailed, and even the smallest defects can be detected by them. The distortion-free imagery of camera modules allows for complete inspections with the aim of determining if quality is being adhered to and standards and specification met.

The magnification camera technology, including high image processing algorithm and machine learning, has caused a more precise way in the field of quality control. The ability to do the inspection in real-time and help spot defects especially when there is no need for manual inspection was made possible, which significantly made the whole process to efficient. Camera modules are widely applied in fields of automotive, electronics, pharmaceuticals and food processing industries bringing out prominent constancy and quality of the goods produced.

Object Recognition and Tracking

The presence of the camera modules with vision algorithms of high complexity and utilization of the machines learning technologies have changed a lot in the object recognition and tracking in industrial automation. Such modules can successfully recognize and follow the specified pathway making the robotic lines deeply mechanized.

Utilizing multi-sensor fusion capabilities, the robots can identify objects, pinpoint their location enhancing orientations and perform tasks with superior accuracy. With this extent of automation it becomes possible to gain productivity, minimize errors as well as improve the functioning of the manufacturing process. Given the ability to perceive and track objects, robots are able to perform tasks such as sorting and stowing in warehouses and distribution centers, and this can result in a productivity surge.

Safety and Security

Camera modules are instrumental in ensuring safety and security in industrial automation environments. They are widely used for surveillance, monitoring, and detecting unauthorized access or potential hazards. Camera modules equipped with infrared or thermal imaging capabilities can identify temperature variations, enabling early detection of fire or overheating in critical areas.

Innovations in camera technology, such as facial recognition and motion detection, enhance security measures in industrial facilities. These modules can be integrated with access control systems, alarm systems, and video analytics software to provide a comprehensive security solution.

There are many more applications for camera modules in industry:

- Predictive Maintenance: Thermal and infrared cameras identify equipment issues before failures through temperature mapping.

- Logistics Monitoring: Camera networks track inventory, optimize storage systems and detect anomalies.

- Augmented Worker Assistance: Wearables with cameras provide remote visual assistance or overlay digital workflows.

- Smart Energy Monitoring: Thermal camera-fitted drones inspect large solar farms to detect underperforming panels.

As modules advance in megapixels, low light capabilities and onboard AI/ML, use cases will rapidly expand into predictive quality, autonomous production and more. This will transform manufacturing through real-time process optimization powered by visual data analytics.

FAQs:

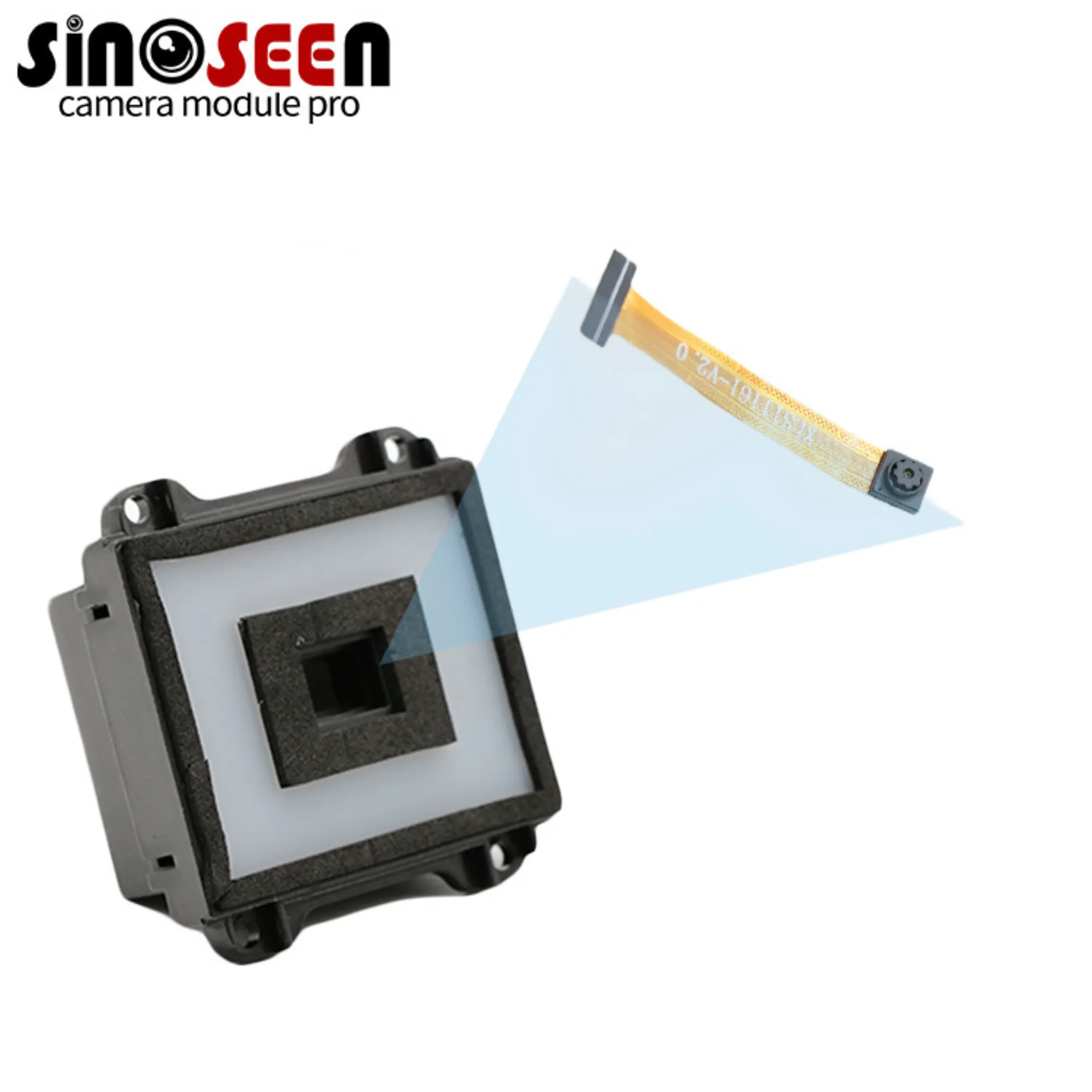

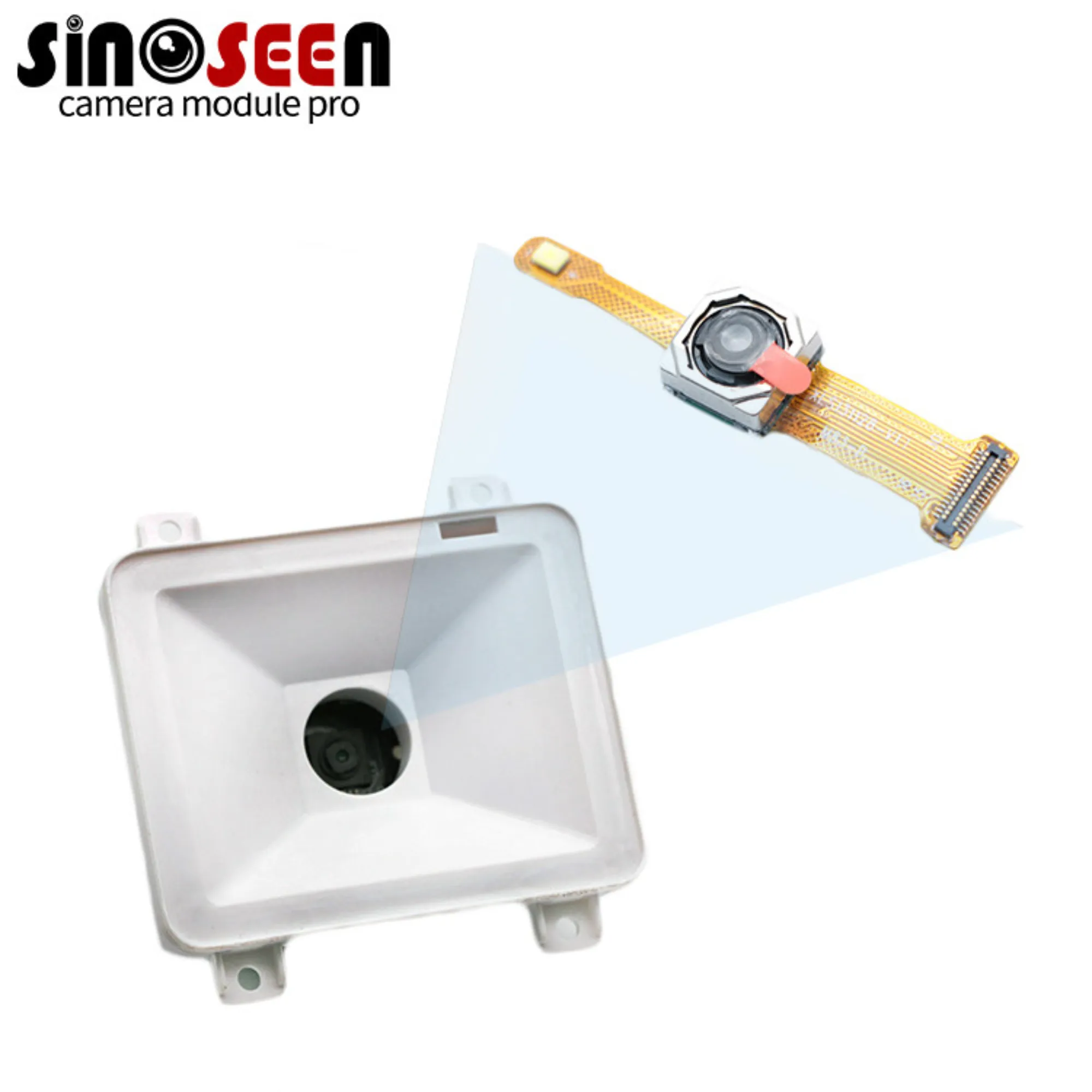

Q: How do harsh factory environments impact camera module design requirements?

A: Ruggedized modules with sealed casings, wide temperature operation and corrosion resistance coatings are needed to withstand vibration, dust and chemical exposures.

Conclusion

Camera modules boost efficiency, quality and safety in manufacturing through vision-enabled automation. Their growing role in industrial IoT will drive continued optimization of production systems.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD