biggest injection molding companies

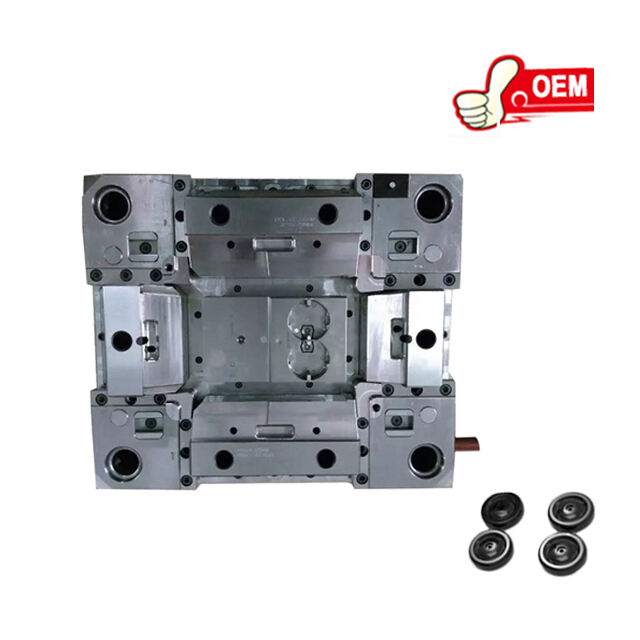

The largest injection molding companies are industry powerhouses, delivering innovative solutions through advanced technology and comprehensive functions. These companies specialize in creating intricate plastic parts and components using high-tonnage injection molding machines. Their main functions include mold design, material selection, precision molding, and post-molding services such as assembly and finishing. Technological features of these firms often encompass robotics, automated systems, and sophisticated software for simulation and process control. This ensures precision and consistency in mass production. Applications span various industries, from automotive and electronics to healthcare and consumer goods, reflecting the versatility and scale of their operations.